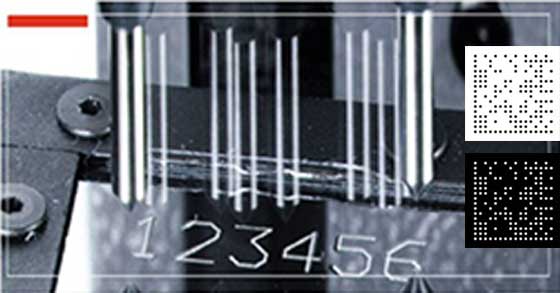

Ever see a 2D barcode etched or dot-peened on a metallic or plastic surface with little or no contrast? Maybe a serial number or part number on a surgical instrument or automotive assembly like a transmission block. This poses a unique problem for reading the barcode.

Barcodes scanners do their reading by illuminating the target code with light and reading the reflected information. However, if there is little or no contrast a conventional scanner will not work. We use a family of Direct Part Marking (DPM) scanners that have unique illumination and special software to solve the application. Datamatrix code is often used in these situations and if dot peened can create a further complication which can be resolved by the firmware in the scanners.

It is always a good idea for us to evaluate the sample codes.

Hey There. I found your blog using msn. This is an extremely well written article. I will be sure to bookmark it and return to read more of your useful information. Thanks for the post. I’ll certainly return.